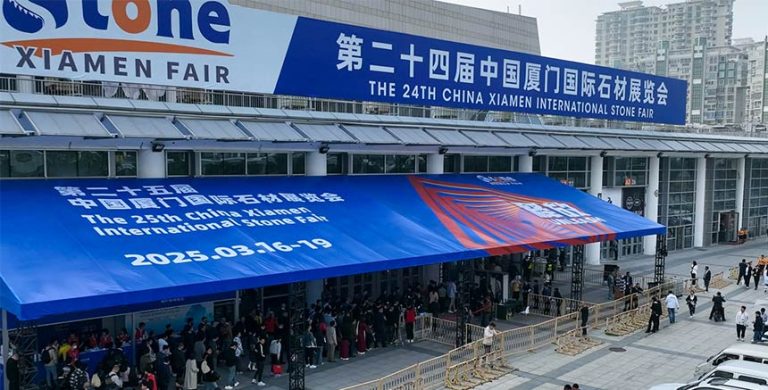

We are proud to announce our participation in the 24th China Xiamen International Stone Fair, one of the most significant events in the global stone…

Crystallized glass slabs, often referred to as nano glass or crystallized stone, represent a significant innovation in architectural and interior design materials. These slabs, known for their exceptional durability, aesthetic appeal, and versatility, are rapidly becoming a preferred choice among designers and builders. This essay delves into the composition, manufacturing process, benefits, applications, and environmental impact of crystallized glass slabs.

Composition and Manufacturing Process

Crystallized glass slabs are made from a blend of natural materials, primarily silica sand, which is subjected to high temperatures and controlled cooling processes. The production involves heating the silica to its melting point, then allowing it to cool slowly, which results in the formation of a crystalline structure within the glass. This process not only imparts enhanced strength and durability to the material but also gives it a unique, marble-like appearance.

The manufacturing process is intricate and requires precise control of temperature and cooling rates to achieve the desired crystallization. Additives such as alumina, lime, and magnesia are often incorporated to improve the physical properties of the glass. The resultant product is a dense, non-porous slab that combines the aesthetic qualities of natural stone with the superior performance characteristics of engineered materials.

Benefits of Crystallized Glass Slabs

One of the primary advantages of crystallized glass slabs is their durability. These slabs are highly resistant to scratching, staining, and thermal shock, making them suitable for high-traffic areas and demanding environments. Their non-porous nature ensures that they do not harbor bacteria or mold, contributing to a hygienic surface that is easy to clean and maintain.

Aesthetically, crystallized glass slabs offer a range of design possibilities. They are available in various colors and finishes, from glossy to matte, allowing for customization to fit any design scheme. The material’s ability to mimic the look of natural stone, such as marble or granite, without the inherent weaknesses of these stones, provides a luxurious yet practical option for designers.

Applications in Architecture and Design

Crystallized glass slabs are versatile and can be used in a multitude of applications. In residential settings, they are popular for kitchen countertops, bathroom vanities, and flooring. Their resistance to moisture and staining makes them ideal for areas exposed to water and high usage. In commercial environments, these slabs are employed in the construction of durable and elegant flooring, wall cladding, and facades.

Moreover, the slabs’ robustness and aesthetic appeal have made them a popular choice in public buildings, such as airports, shopping malls, and hotels. Their ability to withstand heavy foot traffic while maintaining their pristine appearance is highly valued in such settings.

Environmental Impact

The environmental impact of crystallized glass slabs is a consideration of growing importance. The production process, while energy-intensive, utilizes abundant natural materials and can be designed to minimize waste. Additionally, the long lifespan and low maintenance requirements of the material contribute to its sustainability. Unlike natural stone, which involves quarrying and significant environmental disruption, the production of crystallized glass slabs can be more environmentally friendly if managed properly.

Recycling is another positive aspect. At the end of their life cycle, crystallized glass slabs can be recycled into new products, reducing the demand for raw materials and the associated environmental footprint.

Conclusion

Crystallized glass slabs epitomize the fusion of beauty and functionality in modern construction and design. Their remarkable durability, coupled with a wide range of aesthetic options, makes them a versatile and desirable material for a variety of applications. As the industry continues to innovate and address environmental concerns, the future of crystallized glass slabs looks promising. This material not only meets the demands of contemporary design but also paves the way for more sustainable and resilient architectural solutions.